Why AC Compressor Replacement Is Critical for Your Home’s Comfort

When your AC compressor replacement becomes necessary, you’re looking at the heart surgery of your cooling system. The compressor is literally the heart of your AC unit – it circulates refrigerant through the system to remove heat from your home.

Quick Answer: AC Compressor Replacement Overview

- Professional installation required – specialized tools and EPA certification needed

- Cost range: $800-$2,300 for parts and labor combined

- Timeline: Typically 4-8 hours for complete replacement

- Lifespan: New compressor should last 10-15 years with proper maintenance

- Signs you need replacement: Warm air, loud noises, frequent tripping of circuit breaker

Your AC compressor works by compressing refrigerant gas and pumping it through your system. When it fails, you’ll notice warm air blowing from your vents instead of that blessed cool relief during hot summer days.

The stakes are high when your compressor goes bad. A failed compressor doesn’t just mean discomfort – it can cause strain and wear on your entire system, potentially leading to more expensive repairs and skyrocketing utility bills.

Most compressors last between 10 and 15 years with proper maintenance. But when they fail, replacement isn’t a DIY weekend project. It requires specialized equipment, EPA certification for refrigerant handling, and electrical expertise that only trained technicians possess.

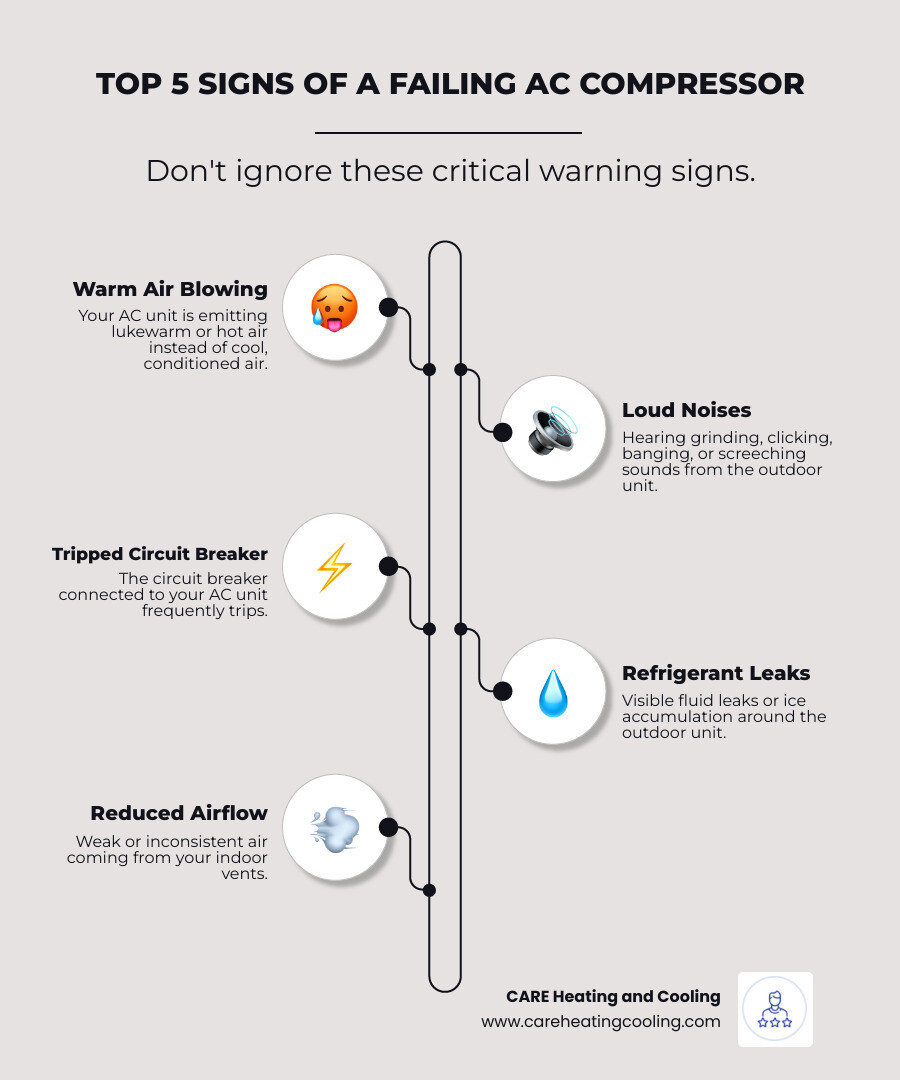

Telltale Signs and Causes of a Failing AC Compressor

Your AC compressor is the hero of home comfort, especially during sweltering Ohio summers. It has a lifespan of 10 to 15 years with proper maintenance, but when it falters, the signs are clear. Ignoring them strains your entire AC system, leading to more repairs and higher utility bills. A bad compressor stops cooling your home, so timely diagnosis is crucial.

Symptoms Your Compressor is in Trouble

Recognizing the early warning signs of a failing AC compressor can save you from headaches and future expenses. Here are the most common symptoms:

- Loud Noises: If your outdoor AC unit starts making unusual noises, it’s likely the compressor. Listen for:

- Banging or Clanking: Often signals a loose component or a connecting rod issue.

- Clicking: A single click when the compressor engages is normal, but constant clicking could indicate a clutch or electrical issue. If your AC makes clicking noises in Westerville, it’s worth investigating.

- Grinding or Squealing: These sounds often point to worn bearings or internal mechanical failure.

- Warm or Lukewarm Air: If your vents blow air that isn’t cold, the refrigerant isn’t circulating properly. When your AC is blowing hot air, the compressor is usually the culprit.

- Tripped Circuit Breaker: A failing compressor may draw too much power, causing your circuit breaker to trip repeatedly. This safety mechanism prevents electrical damage. Understanding why your AC trips the circuit breaker is important, as it could indicate a serious electrical short or a struggling compressor.

- Leaking Fluid: A refrigerant leak from or around the compressor, often with an oily residue, strongly indicates internal damage or seal failure.

- Reduced Airflow: While dirty filters or duct problems can cause reduced airflow, it can also be a symptom of a struggling compressor. For any of these signs, you need AC repair, and prompt action can prevent further damage.

Why Do AC Compressors Fail?

Understanding the root causes of compressor failure can help prevent future issues and inform decisions about AC compressor replacement.

- Low Refrigerant: Low refrigerant is a major cause of failure. It carries lubricating oil, and if levels are too low, the compressor can seize. Signs of refrigerant leaks in your AC should never be ignored.

- Dirty Coils: Dirty indoor and outdoor coils can’t transfer heat effectively. This forces the compressor to work harder, leading to overheating and premature wear.

- Electrical Failure: Issues like a faulty capacitor, failing motor winding, or inconsistent power supply can cause electrical overload and compressor burnout.

- Lack of Maintenance: Skipping annual tune-ups allows small issues to escalate. Regular maintenance is key to extending your unit’s life.

- Contaminants in the System: If the system isn’t properly cleaned after repairs, or if a failed compressor sent debris through the lines, contaminants can damage the new compressor. A thorough system flush is often recommended during AC compressor replacement.

- Blocked Suction Lines: Blockages in the refrigerant lines can restrict flow back to the compressor, causing it to overwork and overheat.

- Incorrect Sizing: An improperly sized AC unit can lead to short cycling or continuous running, putting undue strain on the compressor and shortening its lifespan.

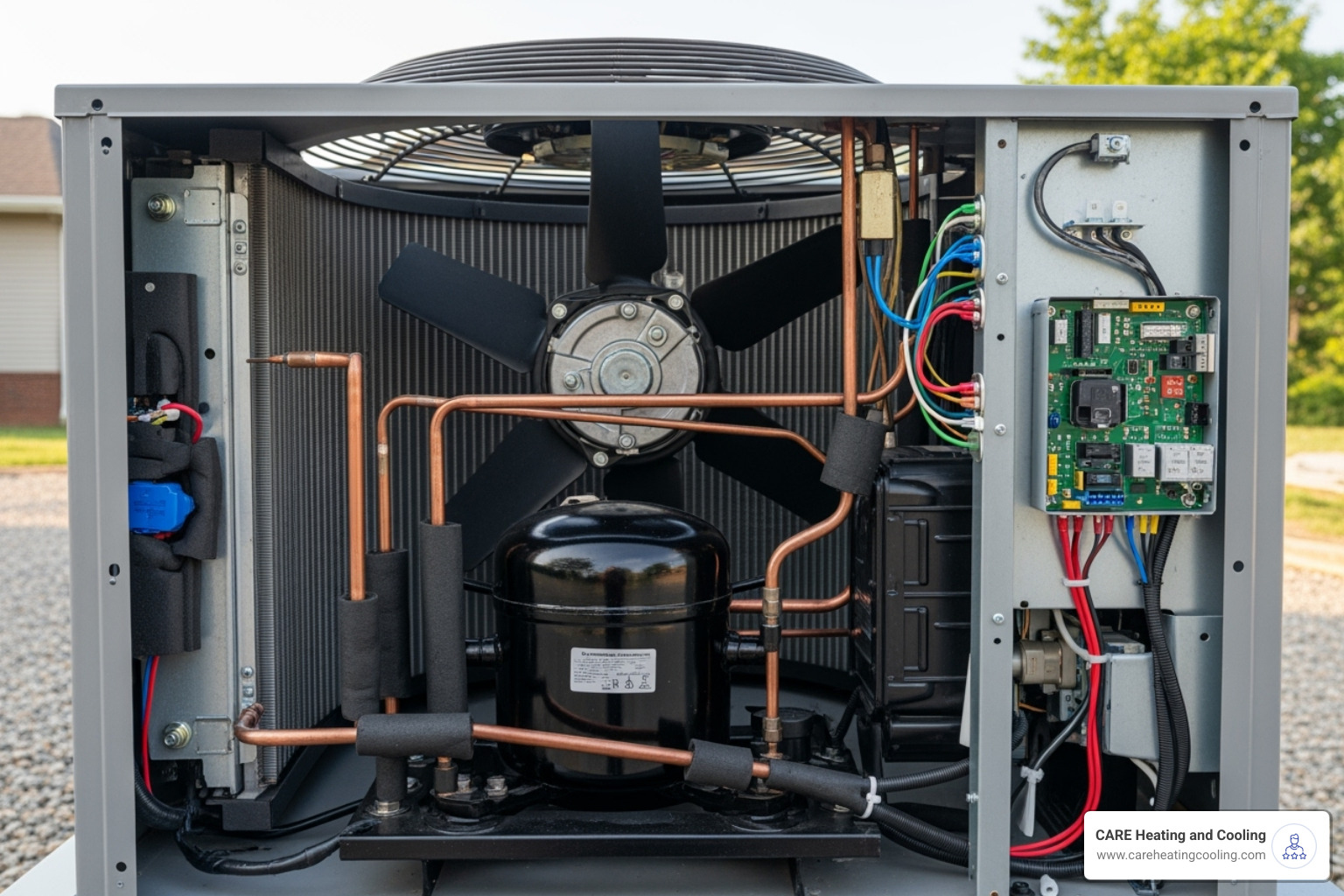

Understanding the AC Compressor Replacement Process: Why Professional Service Matters

Picture this: you’re staring at your outdoor AC unit on a sweltering summer day, and it’s making sounds like a blender full of marbles. The thought crosses your mind – “How hard could it be to replace this thing myself?”

Trust us, we get it. When you’re facing a major repair bill, the DIY route can look pretty tempting. But AC compressor replacement is one of those jobs where good intentions can quickly turn into expensive disasters.

This isn’t like changing a light bulb or unclogging a drain. Replacing an AC compressor is a complex task that demands specialized knowledge, intricate electrical work, and careful handling of pressurized refrigerants. It’s the kind of job that separates the weekend warriors from the professionals.

Why AC Compressor Replacement Should Be Left to Professionals

Let’s be honest about what you’re really dealing with when you attempt AC compressor replacement without proper training. The risks of untrained replacement go way beyond a bruised ego or a few extra trips to the hardware store.

First, there’s your wallet to consider. Most manufacturers will void your warranty faster than you can say “YouTube tutorial” if they find unprofessional work on your system. That warranty protection you’ve been counting on? Gone. Any future repairs become your full responsibility.

Then there’s the need for specialized tools that most homeowners simply don’t have lying around. We’re talking about equipment like manifold gauge sets for precise pressure readings, vacuum pumps to remove every trace of moisture from the system, and refrigerant recovery machines. These aren’t exactly available at your local hardware store, and they’re not cheap either.

Safe refrigerant handling is perhaps the most critical concern. These chemicals are under extreme pressure and can cause severe chemical burns or frostbite on contact. The Environmental Protection Agency doesn’t mess around when it comes to refrigerant handling – technicians need EPA certification for good reason.

And let’s talk about the electrical work dangers. Your AC compressor operates on high voltage electricity. One wrong move with the wiring can damage your home’s electrical system, destroy expensive components, or worse – cause serious injury. When your emergency AC solutions system fails, the last thing you want is to create an even bigger emergency.

The Professional Replacement Steps

When you call CARE Heating and Cooling for AC compressor replacement, you’re getting more than just a repair – you’re getting peace of mind. Our technicians are paid to fix units, not sell new ones, which means we’re focused on getting your system running right, not padding our sales numbers.

Here’s what happens when we arrive at your home. We start with a thorough system diagnosis because sometimes what looks like a bad compressor is actually something else entirely. We check electrical connections, test pressures, and examine the entire system before we touch a single bolt.

Safety comes first, so we completely disconnect the power at the circuit breaker. No shortcuts, no “it should be fine” moments. We treat every electrical connection like it could be our last.

Next comes refrigerant recovery using EPA-certified equipment. Every drop of refrigerant gets safely reclaimed – nothing goes into the atmosphere. This isn’t just about following regulations; it’s about doing what’s right for our planet.

Removing the old compressor requires careful disconnection of electrical wiring and refrigerant lines. Each connection gets photographed and labeled so everything goes back exactly where it belongs.

The new compressor installation is where experience really shows. We position and secure the unit with precision, install fresh O-rings and seals, and connect every wire according to manufacturer specifications. No guessing, no “close enough.”

System vacuuming is the step that separates the pros from the wannabes. We pull a deep vacuum for at least 30 minutes, sometimes longer, removing every trace of air and moisture. Even tiny amounts of moisture can freeze and block your system, while air creates pressure problems that kill efficiency.

Recharging the refrigerant requires exact measurements. Too little and your system won’t cool properly. Too much and you’ll damage the compressor. We measure twice, charge once.

Finally, comprehensive system testing ensures everything works perfectly. We monitor pressures, check temperatures, and make sure your home gets the cool, comfortable air you deserve.

This methodical approach to AC repair ensures your AC compressor replacement is done right the first time. No callbacks, no “oops” moments, just reliable cooling when you need it most.

Breaking Down the Costs of an AC Compressor Replacement

When your AC compressor replacement becomes a reality, understanding the financial side helps you prepare for this significant home investment. While costs vary based on several factors, you’re typically looking at a range between $800 and $2,300 for the complete job, including both parts and labor.

This might seem like a hefty price tag, but remember – you’re essentially getting heart surgery for your cooling system. A new compressor should serve you faithfully for another 10 to 15 years with proper care.

What Factors Influence AC Compressor Replacement Costs?

Several key factors determine where your AC compressor replacement cost will fall within that range. Think of it like buying a car – the final price depends on what you’re getting and what’s involved in the work.

The type of compressor makes a big difference in your bottom line. A single-stage compressor typically runs between $500 and $1,000 for the part itself. These are the most basic units that run at one speed – either on or off. They get the job done but aren’t the most energy-efficient option.

Two-stage compressors cost more upfront, usually ranging from $1,200 to $1,800. However, they’re worth considering because they can run at different speeds, providing better comfort and energy savings over time. They’re like having a car with cruise control versus one that only goes full speed.

Labor costs vary significantly based on your location and the complexity of your particular installation. Most HVAC technicians charge between $50 and $150 per hour, and a typical AC compressor replacement takes anywhere from 4 to 8 hours. The total labor portion usually falls between $200 and $1,200.

Your AC unit’s brand and size also play important roles. Some brands use proprietary parts that cost more, while larger units naturally require bigger, more expensive compressors. It’s similar to how luxury car parts cost more than standard vehicle components.

The accessibility of your outdoor unit can affect labor time too. If your condenser is tucked away in a tight space or requires special equipment to reach, expect the job to take longer and cost more.

The Role of Refrigerant and Warranty

Two factors can dramatically impact your AC compressor replacement experience: the type of refrigerant your system uses and whether you have warranty coverage.

Refrigerant type is crucial to understand. If your AC uses R-22 (also known as Freon), you’re facing a challenging situation. This older refrigerant has been phased out due to environmental concerns, making it extremely expensive and hard to find. Sometimes it makes more financial sense to replace the entire system rather than put an expensive new compressor in a unit that uses costly, obsolete refrigerant.

R-410A is the current standard for modern AC systems. It’s more environmentally friendly and much more cost-effective to work with. If your system uses R-410A, you’re in a much better position for both the replacement cost and future maintenance.

Manufacturer warranties can be your financial lifesaver. Most compressors come with warranties lasting 5 to 10 years. If your unit is still under warranty, you might only pay for labor while the manufacturer covers the expensive compressor part.

Checking your warranty status requires finding your unit’s serial number, usually located on a sticker on your outdoor condenser unit. You can often check warranty status on the manufacturer’s website using this number. If you’re not sure how to find your serial number, we’re happy to help you locate it.

Extended warranties can provide peace of mind beyond the manufacturer’s coverage. However, most warranties require professional installation and regular maintenance to stay valid. It’s another reason why working with certified technicians like ours pays off in the long run.

How to Extend the Life of Your New Compressor

Getting a new AC compressor replacement is a big investment, and you want to make sure it lasts as long as possible. The great news? With some simple care and attention, your new compressor can keep you cool for 10 to 15 years or even longer.

Think of your AC system like a car – it needs regular check-ups to run smoothly. Skip the maintenance, and you’ll likely find yourself back where you started, facing another expensive repair sooner than expected.

Regular maintenance is absolutely essential for compressor longevity. We can’t stress this enough – skipping annual check-ups is one of the most common reasons compressors fail early. Professional AC service for longevity and efficiency isn’t just something we recommend to drum up business. It’s genuinely the best way to protect your investment and keep your home comfortable.

Changing your air filters regularly might seem like a small thing, but it makes a huge difference. When filters get clogged with dust and debris, your system has to work much harder to push air through. This extra strain puts pressure on the compressor, causing it to overheat and wear out faster. We suggest changing filters every three months at minimum – more often if you have pets or family members with allergies.

Keeping your outdoor unit clean is another simple step that pays big dividends. Your compressor lives in that outdoor unit, and it’s constantly battling leaves, grass clippings, dirt, and whatever else Mother Nature throws at it. When debris builds up around the unit, it acts like a thick blanket, trapping heat and making your compressor work overtime to stay cool.

Take a few minutes every month to clear away debris from around your outdoor unit. Pull any weeds, rake up leaves, and make sure there’s at least two feet of clear space on all sides. Your compressor will thank you for the breathing room.

Annual professional tune-ups are where we really make a difference in extending your compressor’s life. During these visits, we clean those hard-to-reach coils, check refrigerant levels, tighten electrical connections, and spot potential problems before they turn into expensive repairs. The importance of AC tune-ups goes far beyond just keeping things running – it’s about preventing the kind of strain that kills compressors early.

Don’t ignore warning signs when they pop up. If you hear strange noises, feel warm air coming from your vents, or notice your circuit breaker tripping, call us right away. These seemingly small issues can quickly snowball into major compressor problems if left alone. Prompt repairs save you money in the long run and keep your system running efficiently.

By following these straightforward maintenance steps, you’re not just protecting your new compressor – you’re ensuring your entire AC system runs efficiently, keeps your energy bills reasonable, and provides reliable comfort for many years to come.

Frequently Asked Questions about AC Compressor Replacement

When it comes to AC compressor replacement, we hear the same questions from homeowners time and time again. It’s completely understandable – replacing your compressor is a big decision, both financially and for your family’s comfort. Let’s walk through the most common concerns we encounter and give you the straight answers you deserve.

How long does an AC compressor last?

Here’s the honest answer: most AC compressors will serve you faithfully for 10 to 15 years. But that’s not the whole story. Think of your compressor like the engine in your car – how long it lasts depends entirely on how well you treat it.

Maintenance makes all the difference. We’ve seen compressors that were babied with annual tune-ups still running strong at 18 years old. On the flip side, we’ve replaced compressors that barely made it to 8 years because they were neglected.

Your local climate plays a role too. Here in Ohio, where your AC works hard during those sticky summer months, compressors face more stress than in milder climates. The quality of your original installation and whether your system was properly sized for your home also impacts longevity.

The bottom line? With regular professional maintenance and prompt attention to any issues, your compressor should easily reach that 15-year mark – and possibly beyond.

Should I repair or replace my AC compressor?

This is probably the toughest question we help homeowners answer. It’s not just about the immediate cost – it’s about making the smartest long-term decision for your family and your wallet.

Age is the first factor we consider. If your AC unit is less than 7 years old and has been well-maintained, AC compressor replacement often makes perfect sense. You’ll get many more years of reliable service from a system that’s still in its prime.

But when your system is approaching or past that 10-15 year mark, we need to have a different conversation. That’s when we apply what we call the “50% rule.” If replacing your compressor costs 50% or more than installing a brand-new AC system, replacement usually wins out financially.

Overall system health matters tremendously. During our assessment, we’re looking at the big picture. Are your coils showing wear? Has your unit been breaking down frequently? Are other major components nearing the end of their lives? Sometimes a failing compressor is just the first domino to fall, and investing in a complete system replacement saves you from a series of expensive repairs over the next few years.

This decision process is very similar to when to replace vs repair a heat pump – it all comes down to evaluating the total system health and long-term value for your specific situation.

Can a bad compressor damage other parts of my AC system?

Unfortunately, yes – and this is why we always stress the importance of addressing compressor issues quickly. A failing compressor doesn’t just affect cooling; it can trigger a cascade of problems throughout your entire AC system.

System strain is the immediate concern. When your compressor struggles, every other component has to work overtime to compensate. Your fan motor, capacitors, and electrical connections all face increased stress, leading to premature wear and potential failure.

But here’s the really concerning part: contamination risk. When a compressor fails internally – maybe the bearings wear out or the motor burns out – it releases metallic debris and acidic contaminants into your refrigerant lines. This contaminated oil and debris doesn’t just stay put. It circulates throughout your entire system, clogging the delicate passages in your condenser, evaporator, and expansion valve.

This is exactly why we always perform a thorough system flush during AC compressor replacement. Without this crucial step, your shiny new compressor could fail within months due to contamination from the old unit.

The domino effect is real. We’ve seen too many cases where homeowners delayed addressing a bad compressor, hoping it would somehow get better. What started as a single repair turned into needing a new condenser, evaporator coil, and refrigerant lines. Suddenly, a manageable repair bill became a major expense that could have been avoided with prompt action.

The good news? Early detection and professional intervention can prevent most of these common AC repair issues and expert solutions. That’s why we always encourage homeowners to call us at the first sign of trouble – it’s much easier and less expensive to fix one problem than to deal with the chain reaction that follows.

Trust the Experts for Your AC Compressor Needs

When your AC compressor starts acting up, it’s tempting to think about tackling the repair yourself. We get it – nobody likes unexpected expenses, especially big ones. But as we’ve covered throughout this guide, AC compressor replacement isn’t your typical weekend DIY project. It’s more like performing heart surgery on your cooling system.

This is a complex job that requires professional expertise, specialized equipment, and strict safety protocols. You’re dealing with high-voltage electricity, pressurized refrigerants that can cause serious injury, and EPA regulations that require proper certification. One wrong move can turn a single repair into a much more expensive problem – or worse, put your safety at risk.

At CARE Heating and Cooling, we’ve built our reputation on doing right by our customers. We’re proud recipients of the BBB Torch Award for Ethics, which isn’t something companies get by accident. It’s recognition of our commitment to honest, transparent service.

Here’s what makes us different: our technicians are paid to fix units, not sell new ones. That might sound like a small detail, but it’s huge for you as a homeowner. When we recommend an AC compressor replacement, you can trust it’s because that’s genuinely what your system needs – not because we’re trying to boost our sales numbers.

This customer-centric approach means we’re always looking for solutions that make sense for your home and your budget. If your compressor can be repaired cost-effectively, we’ll tell you. If replacement is the smarter long-term choice, we’ll explain why. No pressure, no sales pitches – just honest expertise.

We understand how stressful it can be when your AC goes down, especially during those brutal Ohio summers. That’s why we focus on getting your home comfortable again as quickly and efficiently as possible. Our team handles every aspect of the AC compressor replacement process with the care and attention your home deserves.

When you’re dealing with a failed compressor, don’t let the stress get to you. Let our experienced professionals take care of the complex work while you focus on staying cool. We serve Westerville, Lewis Center, and the surrounding communities with the same ethical standards and quality service that earned us our reputation.

Ready to get your AC back up and running? Schedule your AC repair in Lewis Center, OH or anywhere in our service area. Experience the CARE difference – where fixing your system right the first time isn’t just our job, it’s our promise.